-

- OVM Post-tensioning System

- Nuclear Power and LNG Engineering Applications

- Assembled Connection Technology for Prefabricated Piers

- Multi-strand Stay Cable System Solutions for Cable-stayed Bridge

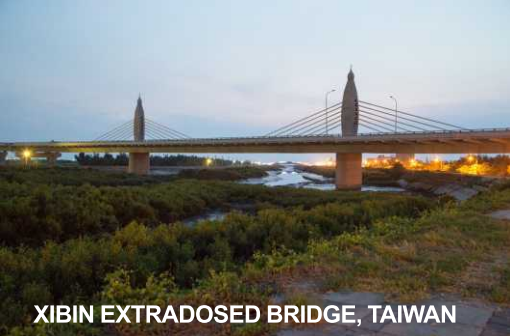

- Cable System Solutions for Extradosed Bridge

- Parallel Wire Stay Cable System(PWS) for Cable Stayed Bridge

- Sulotions of Carbon Fiber Reinforced Composite Materials for Post-tensioning System

- Cable System Solutions for Arch Bridge

- External Post-tensioning System Solutions

- Bridge Anti-seismic Solutions

- Expansion Joints Solution System

- Building Anti-seismic Solutions

- Structural Inspection and Reinforcement System Solutions

- Lifting, Pushing, or Rotating of Overweight Structure

- Underground Space - shield Tunneling, Foundation Pit Support Equipment and Systems Solutions

- Structural Inspection and Reinforcement System Solutions

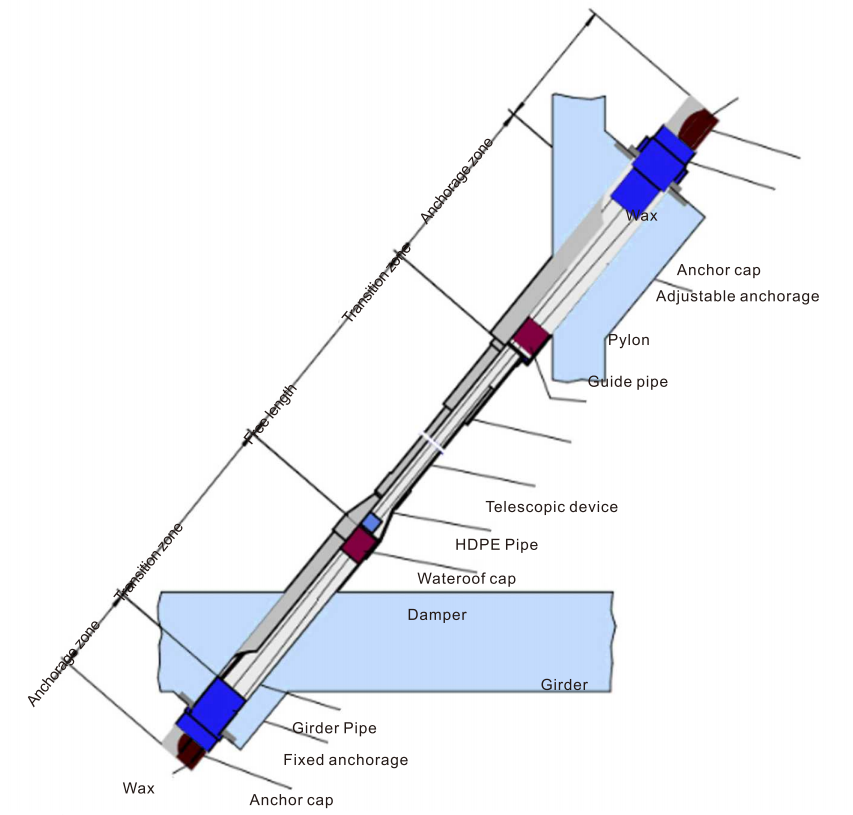

OVM250 Multi-Strand Stay Cable System

OVM250 stay cable system can be divided into three parts:

· Anchoragezone-anchorage,anti-corrosion agent,sealingdevice,bearing plate,guide pipe and cap, etc.

· Transition zone-damper,collar, HDPE pipe connector andwaterproof cap

· Freelength-PE sheathed strands and outer HDPE pipe

(Adjustable anchorage could be altematively placed at deck or pylon as per actual bridge project demand )

Main Advantages

Tests

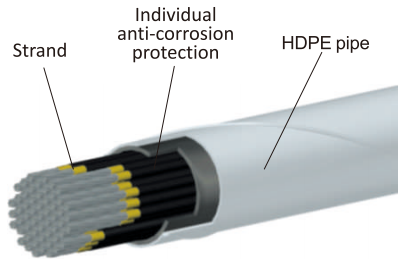

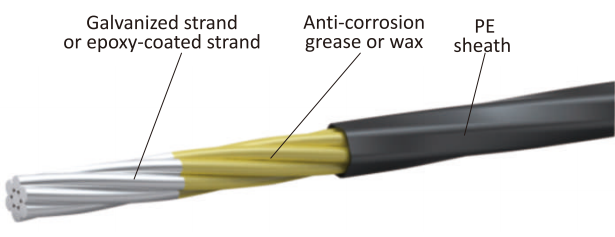

OVM Stay Cable

The cable consists of a bundle of individually PE sheathed,low relaxation,galvanized or epoxy-coated strands, the void between strand and PE sheath is filled by anti-corrosive grease or wax.

Wide size range of cable

The size range of OVM multi-strand stay cable system varies 12 to 160 strands per anchorage.

The larger capacity could be customized according to client's requirement.

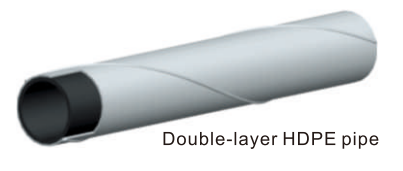

HDPE pipe

HDPE pipe is the outermost protection of the cable,which isolates thecorrosive matter from cable and resists UV radiation.HDPE pipe isextruded from high-density polyethylene, color could be customized tosatisfy the aesthetic requirements.

Double-layer HDPE pipe is composed of two layers of co-extruded HDPEan inner black layer and an outer colored layer.

Durable Anti-corrosion Protection

The anchorage surface is anti-corrosively treated,and the wholeanchorage assembly are waterproof,and fufill requirments in theClP,fib and PTlrecommendations.

Stay Cable Vibration Controlling

Vibration is hazardous to stay cables. lt is necessary to have stay cable vibrating behavior properly suppressed duringits service life.

Stay cable vibration occurs and exists probably due to main reasons as follows.

· Parametric excited resonance(due to Vehicle/Structure)

· Wind excited vibration(e.g.Vortex/Wake/Chattering/Galloping)

· Rain-wind induced vibration

The most effective solution for vibration control is to increase its structural damp of stay cables. Following measures are commonly executed to control cable vibration :

· To adopt double helix ribs on HDPE pipe, it will change cable appearance state, reduce cable aerodvnamic draa and disturb forming of water flow, can effectivelv inhibit rain-wind induced vibration,reduce vibration amplitude and occurring probability of rain-wind induced vibration on stay cables.

· To install a high damping rubber damper at guide pipe entrance. The high damping rubber damper is desianed and made by applvina high dampina rubber, and can sianificantlv control cable vibration.

· To install built-in Viscous Shear Damper (VSD) at guide pipe entrance. The viscous shear damp is designed and made by applying principle of viscous resistance occurs when fluid goes through staggered spiles,and can siqnificantly control cable vibration.

· To Install external permanent magnet adjustable magnetorheological damper at free length of stay cable. The magnetorheological fluid provides damping force and the permanent magnet functions adjustment and controlling behavior. The damper can afford sufficient and adjustable damping force,to obtain the most optimal damping performance on stay cable.

High Damping Rubber Damper

Viscous Shear Damper(VSD)

Type HDMR Permanent Magnet Adjustable Magnetorheological Damper

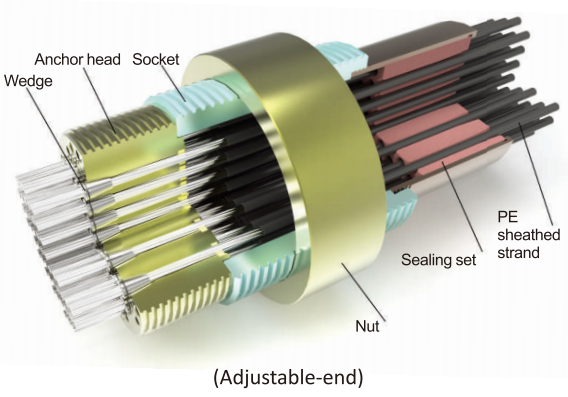

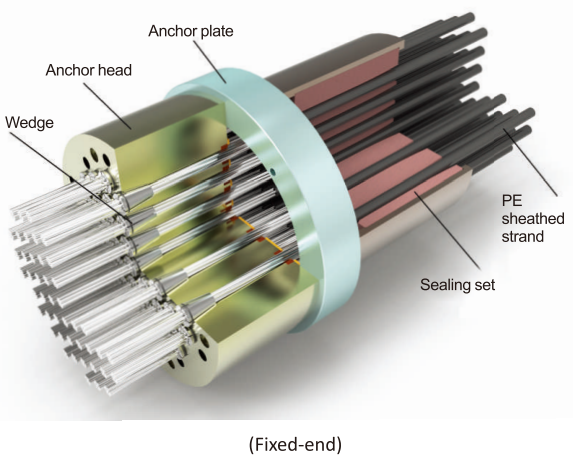

Anchorage zone includes adjustable and fixe danchorages,the cable force is transferred to bridge deck/pylon via anchored wedges.

· OVM250 Stay Cable Anchorage consists of Adjustable and Fixed Ends.

· Strand is stressed and anchored by wedge individually. Cable load is successively transferred through anchored wedges,anchor socket, bearing plates to structure.

· Adjustable anchorage is fitted by a ring nuton anchor plate. lt could be alternatively placed at upper or lower sides accordingto actual engineering requests and it permit to stress strands at both sides.

· Except wedges being seated in and rigidly contacted with conical holes of anchor plate,there is no other rigid contact occurrences along full length of cable and it avoid fretting fatigue and hence well enhance the entire system's fatigue performance.

· The ring nut on the threaded anchor socket enables to integrally adjust cable forceand length. individual strand or entire cable are inspectable and replaceable.

· Surface of anchorage is with galvanization for temporary corrosion protection. Stable and durable filler are filled inside of anchorage to provide good corrosive protection on anchoring and tensile elements;

· Good water tightness performance by being installed with sealing device.

· Circular arc being set out at deviating entrance area to avoid stress concentration on strands and anchorage.

High anchoring and fatigue performance

OVM multi-strand stay cable system has been consistently improved based on numerous of tests in independent laboratories both at home and abroad, such as CTL USA and EMPA Switzerland. lt is a proven system has good static and fatigue performance according to latest CIP, fib and PTl recommendations.

Fatique & Tensile Test of OVM 250-139 Stay Cable System

· Test standard:fib Bulletin 30:Acceptance of stay cable systems using prestressing steels(2005).

· The individual strand is galvanized, greased and HDPE-sheathed, with nominal diameter 15.24mmUTS 1860 MPa.

· Resistance to 250 MPa stress range which exceeds specified as 200MPa at 45% of GUTS for2 million cycles in ClP, fib and PTl.

Fatigue & Tensile test ofOVM250-156 Stay Cable

· Test standard: fib bulletin 30: Acceptance of stay cable systems using prestressing steels(2005)

· The individual strand is galvanized, grease and HDPE-sheathed, with nominal diameter 15.7mm.UTS 1860MPa

· 45% of GUTS, 200MPa stress range, 2 million fatigue cycles

Dynamic watertightness performance

A large numbers of bridges reveal that the most cable corrosion occurs at the lower anchorages,which is because of weak watertightness performance.OVM multi-strand stay cable system has been tested for its dynamic watertightness performance been proven to comply with latest ClP fib, and PTl recommendations.

Liuzhou OVM Machinery Co., Ltd.

Tel: +86-772-3116402

Website: www.ovm.cn

E-mail: sales@ovm.cn

Address: No.1 Yanghui Road, Liuzhou, Guangxi, 545006, P.R.China.